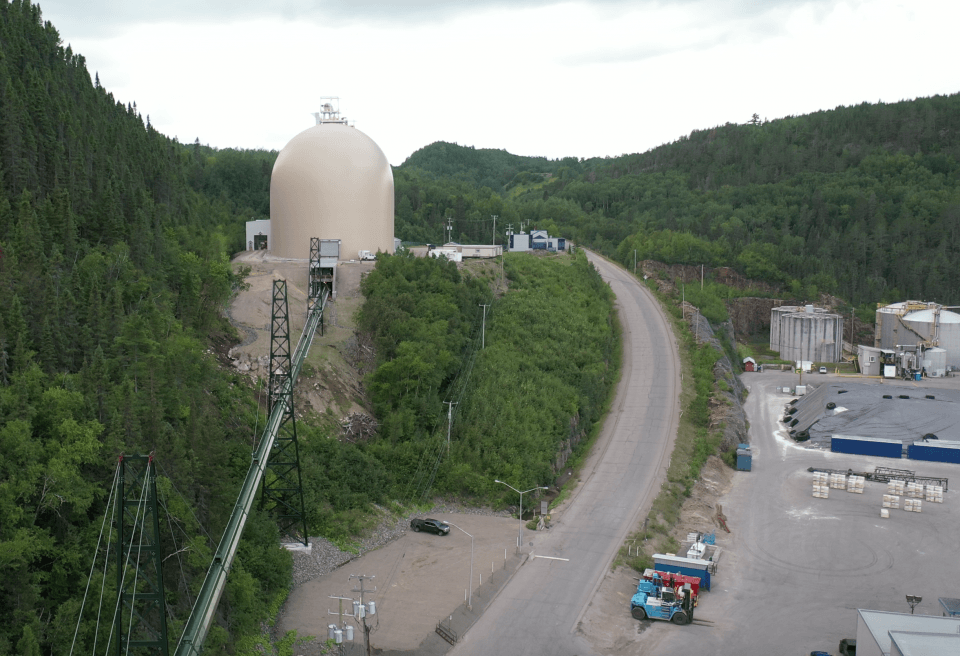

Two powerful elements at the Barrette-Chapais wood-pellet terminal in Quebec, Canada, are the 100-meter Belt Conveyor and 250-meter Tubulator that stretch from the domes near the mountain all the way to the dock. Bruks Siwertell provided the system and has written about it in detail here.

Wood-pellet producer Barrette-Chapais contracted with Dome Technology to build two DomeSilos, measuring 120 feet (36.5 meters) in diameter and 131 feet (39.9 meters) tall and each capable of storing 21,000 metric tons, at the Port of Saguenay. Because of their geometry DomeSilos are able to store more product in a smaller footprint, stacking pellets deeper and storing them all the way to the structure’s apex.

Dome Technology also acted as construction manager, supervising Canadian crews on all equipment installation—load-out system, bucket elevator, and conveyance. The Belt Conveyor and Tubulator are central to the reclaim system, and according to Granule 777 general manager Yann Sellin, the Bruks conveying system is the most exciting new feature for the company.

The new air-supported conveyor system can convey pellets at 800 tons per hour. The complete Barrette-Chapais project summary can be found here.