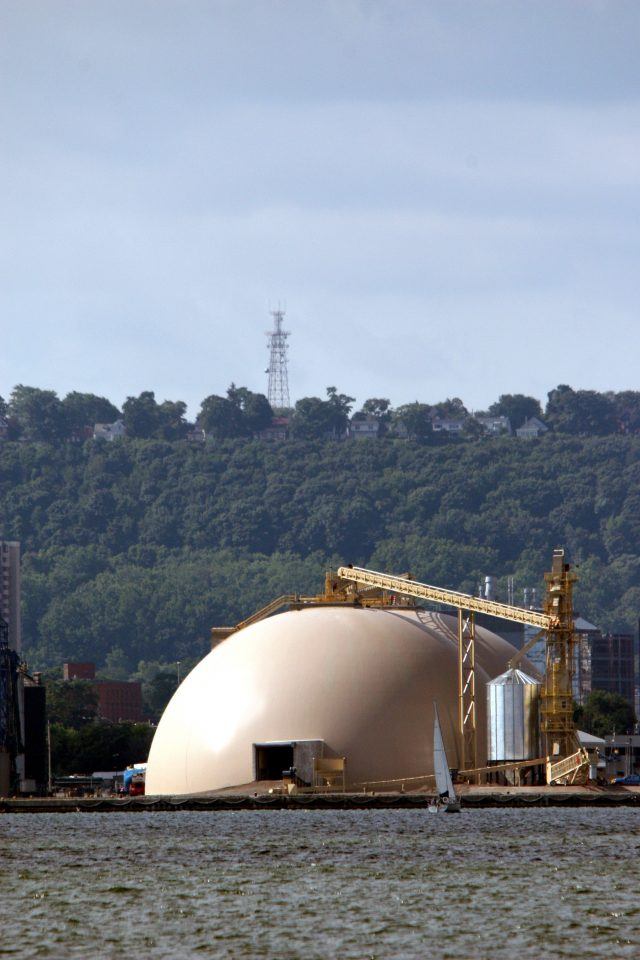

When rivers are too high for barges to navigate, processors face two big questions: How to maintain product quality when shipping conditions aren’t optimal, and how to keep the plant running when product can’t be moved down the river for two months. A dome structure can hold multiple months of grain with the ability to circulate it, providing a way to stay afloat until shipping conditions improve. A dome also stores large quantities of grain to help with capture and carry when merchandisers see those opportunities.

Processors who select a dome—which can range in capacity from 4,000 to 200,000 tons—are able to buy grain regardless of what Mother Nature is up to, providing the solution to these two major concerns. “If you’re a processor, you need to be able to continue processing even if the river is down for three months, and the dome will allow you to do that,” Dome Technology sales manager Heath Harrison said.

Domes are able to store more than silos with similar dimensions, and increased storage is possible based on the dome’s curvature. Because a dome can support pressure at all points of the structure, product can be stored right up to the apex.

But that produces a substantial pile of grain, so maintaining climate conditions is a must. This starts with the dome itself. First, a PVC membrane covering the entire dome prevents moisture entrance. Second, the combination of the waterproof membrane, polyurethane foam insulation and reinforced concrete structure prevents extreme interior temperature fluctuation. These features reduce heating and cooling of the walls and air inside, preventing condensation.

Domes can be equipped with multiple systems that help maintain ideal conditions in long-term grain storage:

Aeration systems

Circulation and adequate aeration make greater capacity possible. Aeration forces air through piles to keep temps consistent and achieve or maintain long-term storage moisture content. Aeration costs can also be less expensive in a dome because of its seamless, insulated construction. Roof exhaust fans draw humidity from the dome.

Temperature cables

A cable array hung from the dome roof monitors humidity and temperature, alerting plant managers when the environment ceases to be ideal.

CO2 monitoring system

Since the dome has the ability to draw from any given reclaim gate, any pockets of grain identified as deteriorating or infested can be drawn out of the structure.

With these monitors, processors can keep a close eye on product and address concerns in short order.

Mix and blend

The typical grain dome features multiple gates within the foundation; to circulate, product is drawn out of these gates, then conveyed to the top of the dome and reloaded. Terminal managers can also select specific gates to address hot spots, and monitoring systems help identify those. If certain pockets are lower in quality, corresponding gates can be opened to various percentages with gates adjacent to high-quality product opened as well. “The dome’s blending capability will create a consistent product for the customer or end user,” Harrison said.

For processors, shuttle loaders and exporters, these blending options are essential. A dome is cost competitive with silos when providing the ability to pull from multiple gates, an option limited with steel tanks, which cannot withstand frequent loading and unloading as the pressure of drawdown will cause them to topple.The inherent strength of monolithic construction makes blending or mixing and blending possible.

“Domes allow you to maximize blending capability, giving companies the opportunity to maximize profits and efficiencies,” Harrison said. “The grain industry operates on tight margins, so sometimes throughput and mix and blend are all we have to increase the bottom line. Domes will maximize that bottom line.”

In addition to these benefits, recent construction advances are yielding better results for grain companies. For instance, Dome Technology has pioneered round explosion panels that channel pressure out of the structure, preventing structural damage in the event of an explosion. Also, domes are free-span structures, free of ledges or beams where dust could accumulate.

Companies eager to secure “no-entry” options can explore different reclaim systems that make this possible; Dome Technology’s engineers identify reclaim that delivers necessary throughput and keeps employees safe. Domes can be designed to hold two to three million bushels and still be a no-entry system, helping with safety and labor efficiency.

A turnkey solution

Dome Technology customers work with an in-house team of engineers and construction experts to determine the ideal design and execution of a facility. When all the elements are planned with others in mind, the result is a dome that stores more, monitors product conditions and interior climate, circulates product and does it all seamlessly. A dome is the proactive longterm grain-storage solution for dealing with frustrations of the river and beyond.

Editor’s note: The article above was published in the August 2019 issue of Milling and Grain. Read the full issue online here.

By Rebecca Long Pyper for Dome Technology