When approached by a coal company needing to store coal at the mine and wanting to reclaim 100 percent of product without personnel entering the storage facility, the ideal model was clear.

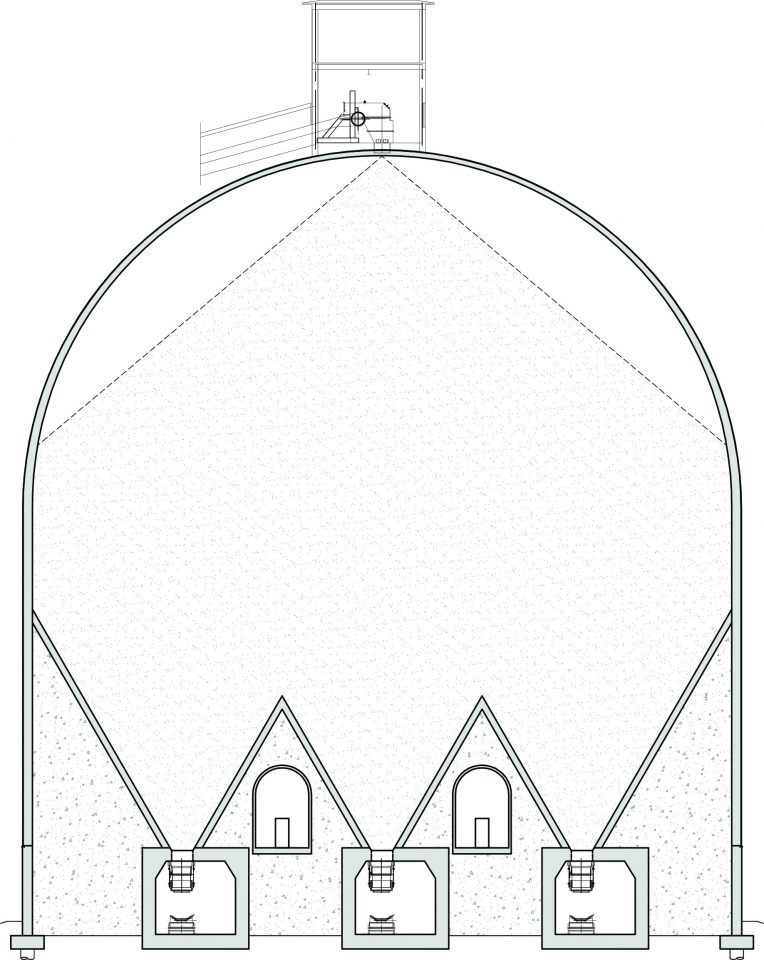

Hypothetically, a DomeSilo that’s 105 feet in diameter and 150 feet tall would provide the desired storage, and to make things work optimally, a full hopper system with chevrons 25 feet tall would be built directly into the dome, eliminating the need for mechanical systems inside.

“This doesn’t require any personnel inside the dome — there’s no mechanical inside the dome to go in and fix. The idea that we can make them really tall and skinny increases the live reclaim,” Dome Technology sales manager Lane Roberts said.

With chevrons hoppers into the dome, product flows easily by way of gravity. And when engineered to the optimal angle, cleaning out the dome is no problem at all, not to mention the likelihood of aging in pile is diminished as product is naturally first in, first out.

But a lot of behind-the-scenes work was required before settling on this customized model.

Engineering the best option

When the customer asked about the optimal guts for its coal storage dome, the first thing the Dome Technology team did was to suggest, based on experience, the number of tunnels thought to be best, which was three. But the second step was determining the minimum angle at which product would flow properly. This angle would determine the angle of chevrons within the dome.

After identifying the hopper angle, Dome Technology calculated exactly how the company could save money while still achieving the reclaim and storage it wanted. The team tested different scenarios, changing up the number of tunnels and the number of chevrons but always keeping that hopper angle in mind. After figuring the costs of the different models, the team was confident more tunnels would cost less than more chevrons.

Chevrons aren’t a cheap install; each one requires massive amounts of concrete and steel. Increasing the number of tunnels would mean the chevrons wouldn’t have to reach so high, dropping that cost substantially.

“We ran the model, and when we went down to two tunnels from three, the chevrons got so tall and the amount of concrete to form the chevrons doubled,” Roberts said, increasing costs in construction materials (not to mention labor).

Returning to the original recommendation of three tunnels would also provide greater storage since the taller the chevron, the more space it consumes inside the dome. Shorter chevrons free up room for product.

By finding the perfect balance — what number of tunnels best complements the appropriate chevron angle — companies like this can achieve necessary storage and save money. It’s the principle of design-build at its finest.

Why a full-hopper system works well for coal

The full-hopper system provides first-in, first out reclaim desirable with types of coal prone to spontaneous combustion. In general, domes are well suited for coal storage. DomeSilos make more storage possible within a smaller footprint — the facility is built up, not out — so companies can store more in a smaller footprint than warehouses or flat storage would allow. And the DomeSilo naturally protects product too — an important quality when working with volatile coal.

By Rebecca Long Pyper for Dome Technology

Editor’s note: This is an excerpt from a Dome Technology article published in the May/June issue of World Cement. Full text with details about dealing with dust, preventing fire, and preserving product integrity while protecting the environment is available starting on page 46 at https://bit.ly/2gjEVkI.