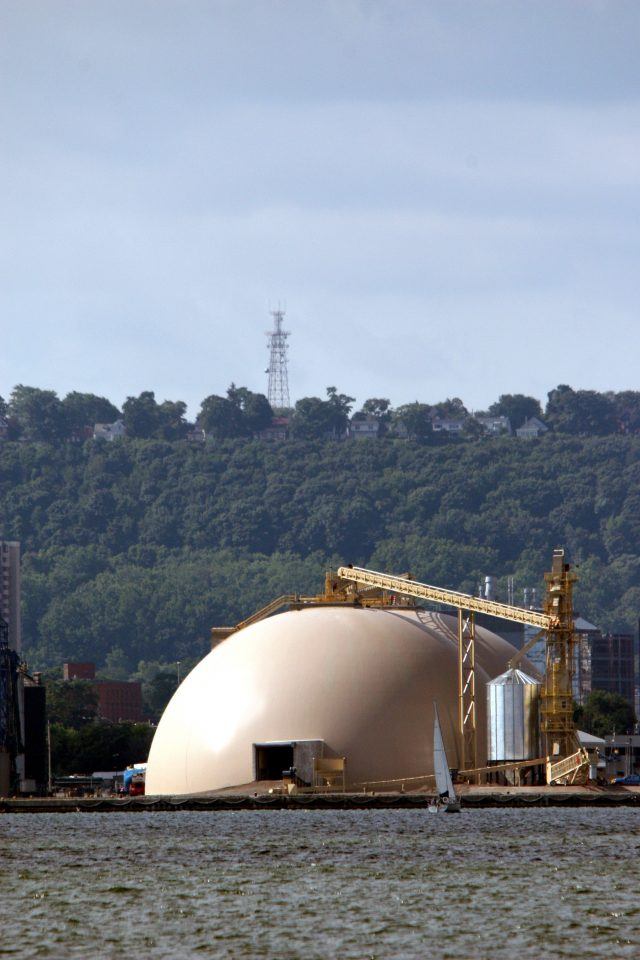

When rivers are too high for barges to navigate, grain processors face two big questions: How to maintain product quality when shipping conditions aren’t optimal, and how to keep the plant running when product can’t be moved down the river for two months. A DomeSilo can hold multiple months of grain with the ability to circulate it, providing a way to stay afloat until shipping conditions improve. A dome also stores large quantities of grain to help with capture and carry.

Processors who select a DomeSilo are able to buy grain regardless of what Mother Nature is up to. “If you’re a processor, you need to be able to continue processing even if the river is down for three months, and the dome will allow you to do that,” Dome Technology sales manager Heath Harrison said.

DomeSilos can store more than silos with similar dimensions, and increased storage is possible based on the dome’s curvature. Because a dome can support pressure at all points of the structure, product can be stored right up to the apex.

But that produces a substantial pile of grain, so maintaining climate conditions is a must. This starts with the dome itself. First, a PVC membrane covering the entire dome prevents moisture entrance. Second, the combination of the waterproof membrane and polyurethane foam insulation with the reinforced concrete structure prevents extreme interior temperature fluctuation. These features reduce heating and cooling of the walls and air inside, preventing condensation.

DomeSilos can be also be equipped with multiple systems that help maintain ideal conditions in long-term grain storage, like aeration systems, temperature cables, and CO2 monitoring systems.