Selecting a new grain-storage solution is a big decision, but with it comes the opportunity for big, economical growth.

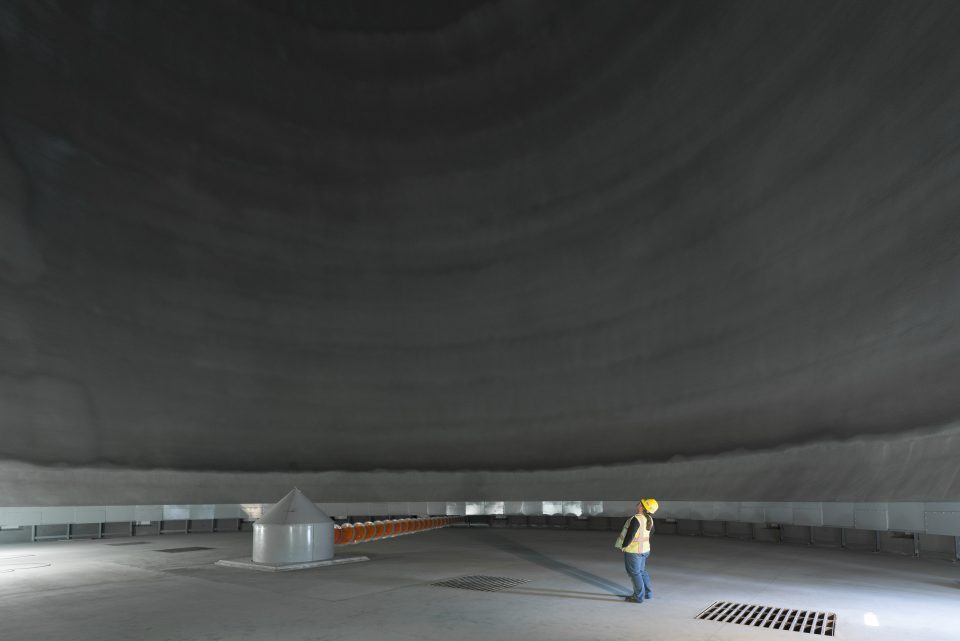

Dome Technology builds bulk-storage domes with economic advantages that come from steel-reinforced concrete construction. A dome’s strength provides a few key benefits that combine to potentially improve a company’s bottom line.

1. Large capacity.

Oftentimes those who buy land on a port get less property for their money, requiring decisions on how to achieve the necessary storage on a smaller parcel of land.

Because of its height, a dome allows companies to stack product deeper, taking up less property at the site. The double curvature of a dome lends itself to the ability to build up, rather than out, and that curve provides strength at all points of the structure, even near the apex. The entire interior of a dome, then, can be used to contain product.

2. Increased throughput.

The dome tolerates frequent loading and unloading, outperforming steel structures over time. The dome’s tolerance for cyclic throughput is high because of its structural integrity. Filling and emptying will stress any structure, but a dome’s rebar accepts the load without fatigue problems; the stress is not channeled to weak spots like bolts or seams because there aren’t any. The robust nature of a dome doesn’t require regular maintenance, and the concrete shell’s lifespan is indefinite.

3. Increased mix and blend.

For processors, shuttle loaders and exporters, blending is essential. The strength of the dome makes blending or mixing and blending possible. A dome is cost competitive with silos when providing the ability to pull from multiple gates, an option limited with steel tanks.

“Domes allow you to maximize blending capability, giving companies the opportunity to maximize profits and efficiencies,” Dome Technology sales manager Heath Harrison said. “The grain industry operates on tight margins, so sometimes throughput and mix and blend are all we have to increase the bottom line. Domes and DomeSilos will maximize that bottom line.”

In addition to these benefits, recent construction advances are yielding better results for grain companies. For instance, Dome Technology has pioneered round explosion panels that channel pressure out of the structure, preventing structural damage in the event of an explosion.

Companies eager to secure no-entry options can explore different reclaim systems that make this possible; Dome Technology’s in-house engineers work closely with customers to determine reclaim that delivers necessary throughput and keeps employees safe.

Lastly, for companies moving product from barge to storage to truck in short order, the Drive-Thru DomeSilo might be the answer. Dome Technology has pioneered the Drive-Thru DomeSilo, a tall, skinny dome with drive-through capability that stores more product on a smaller footprint than a silo of comparable dimensions and allows for direct load-out. The model debuted in the cement industry in the summer of 2018 but is now available for economical grain storage too.

Editor’s note: This is an excerpt from an article published in the March 2019 issue of Dry Cargo International.