It’s well known that wheat farmers enjoyed a strong harvest in 2016, setting records for winter-wheat yields during the 2016/2017 marketing year. And according to the USDA’s June 2017 report, worldwide winter-wheat production for the 2017/2018 season is approaching last year’s yield. In some areas, particularly Russia, weather has been ideal for growing grain.

So what to do with a bumper crop? When grain farmers harvest record amounts of grain, prices drop because supply is abundant. The ideal option, then, is to store grain in such a way that its integrity is preserved until demand increases.

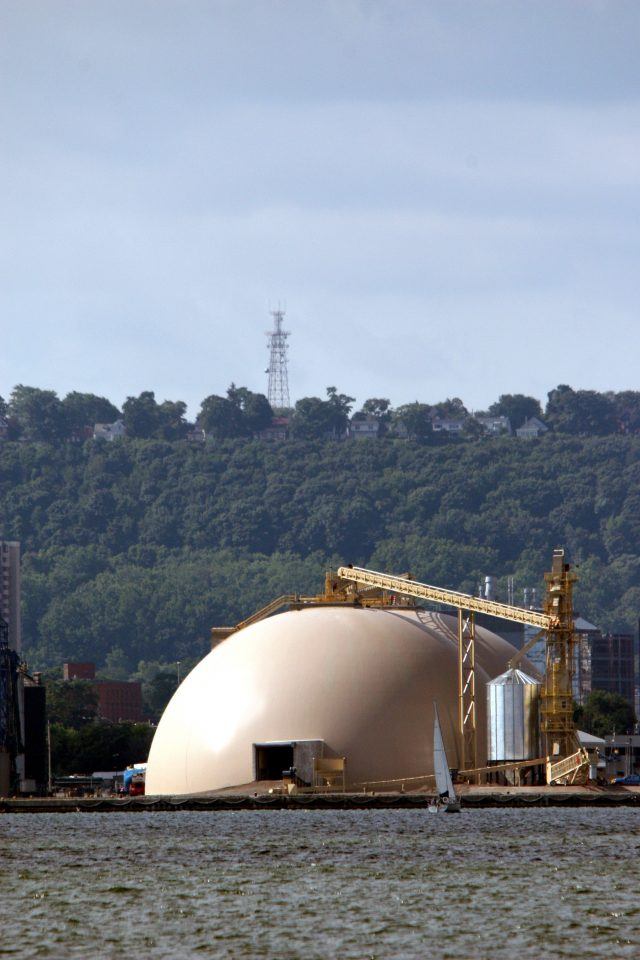

An increasing number of grain producers, large and small, are contracting with Dome Technology to build DomeSilos™ for product protection, granting them the freedom to store and sell on their terms. “A DomeSilo is proven to be an economical and reliable solution for long-term grain storage. It’s a sealed vessel that protects against rodents, bugs and moisture,” said Dome Technology CEO Bradley Bateman.

Each DomeSilo is customized to meet the unique long-term grain-storage needs of the farmers and companies who will use it. But here are a few key benefits present in all domes built for grain:

Cost savings

A dome allows for more storage than a silo with a comparable footprint. A silo’s traditional conical roof cannot support product, so the entire interior cannot be used for storage. Because the hemispherical geometry of a dome renders strength at all points of the structure, the entire interior can be used to contain product.

Traditional bulk storage frequently may require expensive deep-foundation systems based on the amount of weight the structure will hold. But Dome Technology engineers utilize diverse alternative foundation systems that will often reduce deep-foundation costs. Customers can save millions as the need for deep foundations may be reduced.

Costs are cut as domes are built with locally available concrete and steel, and the dome’s double curvature requires fewer construction materials with significantly less waste. And a DomeSilo can be built quickly; once the outer weatherproofing membrane is in place, construction materials and machines move inside, so construction can continue regardless of the weather.

Superior long-term product protection through climate control, pest prevention

A dome staves off boundary issues other structures face. First, the PVC membrane covering the entire dome prevents moisture entrance. Second, the combination of the waterproof membrane, polyurethane foam insulation and reinforced concrete structure prevents extreme interior temperature fluctuation. These features reduce heating and cooling of the walls and air inside, preventing condensation.

Domes can be equipped with multiple monitoring systems that help maintain ideal grain conditions:

- Aeration systems: Aeration forces air through piles to keep temps consistent and achieve or maintain long-term storage moisture content. Besides maintaining integrity, a secondary advantage of climate control is that businesses can safely store product until demand drives up prices. Aeration costs can also be less expensive in a dome because of its seamless, insulated construction.

When grains self-heat, it’s a function of moisture, time and temperature. An aeration system is designed to maintain the moisture and temperature, making sure a dome’s conditions keep grain at its prime. Designed specifically for aerating and maintaining moisture in grain, these systems can typically keep product within 1 to 2 percent of desired moisture content. If product is coming in hot because it’s been sitting in the sun post-harvest, an aeration system can be designed to pull off heat.

Editor’s note: The preceding is an excerpt from a feature published in the Nov. 2017 issue of Milling and Grain. To read the full article, visit this site and click to pages 96-97.

By Rebecca Long Pyper for Dome Technology