Scope of Work

| Domes | Height | Diameter |

|---|---|---|

| #3629 | 108.2ft | 114.8ft |

| #3629 | 33.0m | 35.0m |

Dome Technology contracted with independent energy producer Albioma to build a wood-pellet storage dome in Fort-de-France, Martinique, where Albioma is building the island’s first 100 percent biomass power plant.

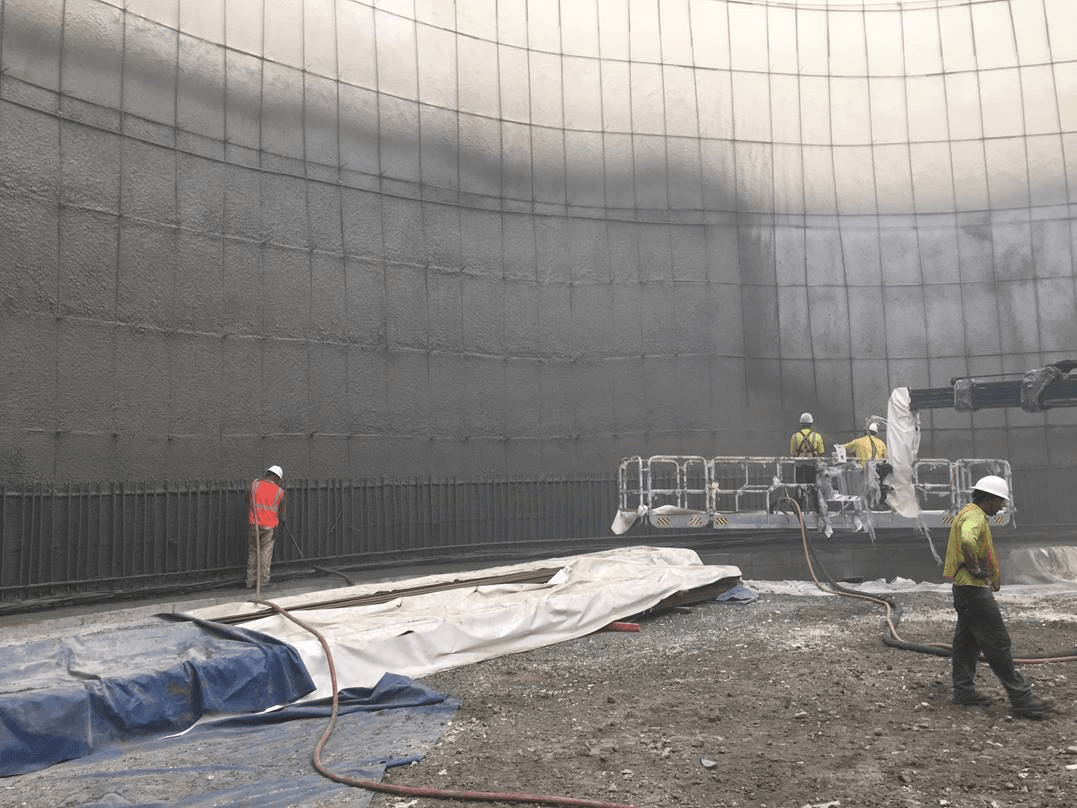

The single dome stands 33 meters tall and 35 meters in diameter, with the ability to store as much as 19,900 metric tonnes of biomass wood pellets. Dome Technology oversaw work for the deep-pile foundations, pile cap, dome shell, and one above-grade tunnel. “The dome will achieve approximately 70 percent reclaim by gravity alone and will have access for a front-end loader to reclaim the remaining 30 percent,” said John Winter, former Dome Technology business developer for European and African projects.

The self-emptying ability for a large portion of the volume was one of the factors that led Albioma to select a dome, said Albioma project director Claude Décamp.

Construction began with soils remediation and deep-piled foundations. “We were on the port area and so close to the water, and so the weight of the dome was a concern there,” Dome Technology lead foreman Eric King said. The soil was especially compromised as much of the “ground” had been placed there years before and was filled with coral and dumped material.

The Dome Technology team dug out two meters of surface material and replaced it with crushed stone. Five hundred stone piles were then installed.

Establishing a solid foundation met the demands of local conditions, where cyclonic and seismic events are common and poor soil is the norm; in fact, Hurricane Matthew hit the island right before inflation, and two earthquakes also took place during construction. “The structure can withstand 200 mph winds, and being the structure it is, the dome can withstand an earthquake as well,” King said, adding that the island is home to a potential volcano as well.

Though flat storage was an option, the large size as well as anticyclonic and anti-seismic accommodations and soil remediation would have required a very high investment cost. The dome was selected for its smaller footprint, less-expensive foundation, lower overall cost, and higher storage capacity, Décamp said.

In addition to constructing the dome, Dome Technology was responsible for installation of the pellet-storage monitoring equipment at the apex, including a stored-product-level monitoring system and an off-gas detection system; also inside, a temperature/heating cable array system monitors product temperature cycles.

Dome Technology additionally supplied and installed a nitrogen-gas piping system below the concrete floor for the customer’s own nitrogen system to be connected for pacifying the product when stored for longer periods. And in accordance with European directives, the team designed and installed ATEX 22 explosion-relief openings and an ATEX 22-rated lighting on the inside of the dome apex.

Albioma is an independent energy producer and world leader in the conversion of biomass into a highly-effective source of energy, in collaboration with its agri-business partners. For more than 20 years, Albioma has operated power plants recovering bagasse, a fibrous by-product of sugar cane, replaced by coal outside the sugar cane harvest. Its unique expertise has enabled Albioma to establish itself as an indispensable partner in the sugar and ethanol industry in the French overseas territories and Mauritius. Albioma is now developing power plants using only biomass, which recover, in addition to bagasse, green waste, and wood-industry residue. Albioma also operates a highly-efficient photovoltaic installation and agricultural anaerobic-digestion units. In 2014 the group, which already had a presence in mainland France, the French overseas territories, and Mauritius, began operating in Brazil, the world’s leading sugar-cane producer.