Scope of Work

| Domes | Height | Diameter |

|---|---|---|

| #692 | 120ft | 108ft |

| #692 | 36.6m | 32.9m |

| #693 | 63ft | 89ft |

| #693 | 19.2m | 27.1m |

Bridgesource’s new two-dome facility in Ogden, Utah, USA, checks all the boxes. Capacity, storage flexibility, and increased distribution? Check, check, check.

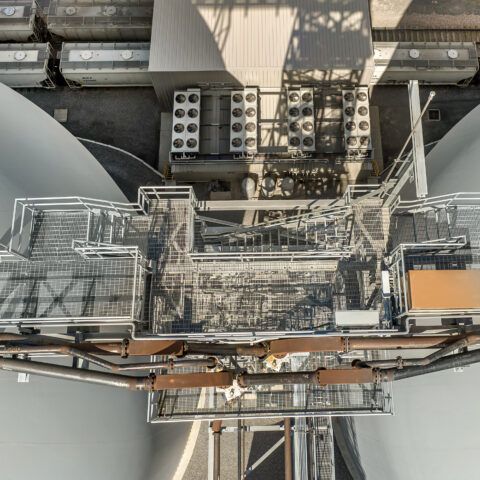

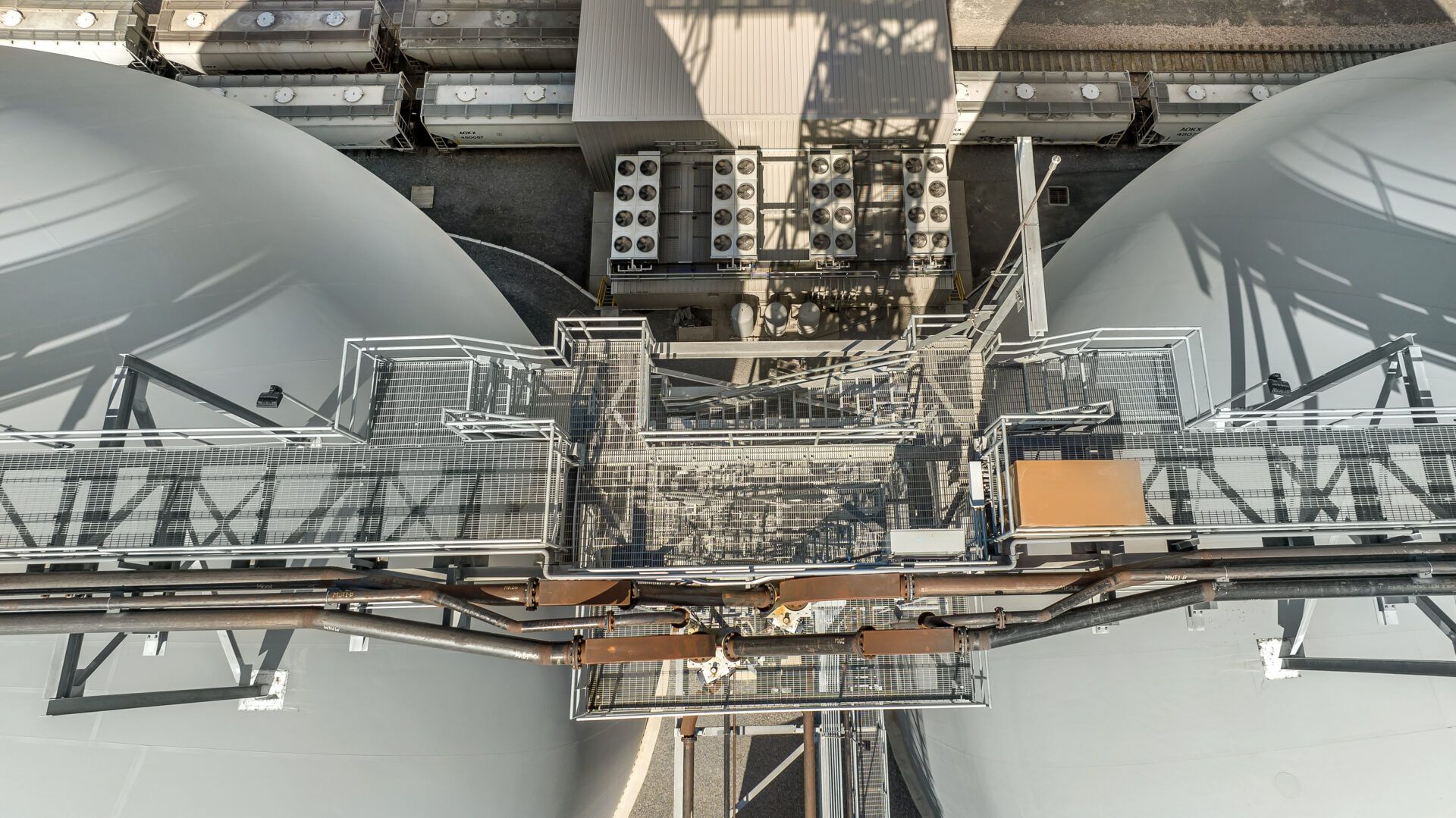

Fly ash or cement is stored in one of two domes, the centerpiece of the storage facility. Each dome is 108 feet in diameter and 120 feet tall with a fly-ash capacity of 25,000 short tons and a cement capacity of 32,000 short tons. A DCL aerated floor system and side discharge provides 99 percent live reclaim. The innovative sloped-floor design allowed for building a vault to house mechanical equipment like blowers underneath the high end of the floor.

Bridgesource, the arm of Clyde Companies that stores and distributes cementitious materials, considered silos and flat-bottom storage, but “as we looked at the amount of storage material we need to store, the dome allowed us to do it with a much smaller footprint. They’re definitely more efficient and more economical,” said division manager Gary England.

Bridgesource receives product on the Ogden rail line. Trains deliver and discharge product into an unloading pit with FLSmidth Fuller-Kinyon pumps inside and a steel building above. From there, product is conveyed to domes for storage.

When product needs to be delivered, FK pumps transport it to one of two 300 short-ton day bins for truck loading. Alternately, it can be transported by a 700-foot pipe from the pit to the on-site ready-mix plant.

Even with a total capacity exceeding 60,000 tons, the domes’ unobtrusive design fits well in the neighborhood. England noted that these aren’t your average industrial eyesores because they provide more storage in a smaller footprint. “They’re not as intrusive as a bunch of tall silos. That’s one of the things we’ve been really happy about—how well they fit into the community,” he said.

But nothing compares to maximized operations. Bulked-up capacity means a place to store product year-round, which gives the company an advantage during the non-peak season. Bridgesource can receive product during months when need is low and distribute it when demand increases. In this way, the company is prepared for its busiest season.