In early 2023 one longtime fertilizer-mining company in Idaho seriously updated and upgraded their conveyance and stacker systems, and Dome Technology was called upon to lend their fabrication and install expertise to the project.

“The additional capacity of the new rail unloading was way beyond what the existing conveyors for the facility could accommodate,” Dome Technology sales manager Heath Harrison said. “We built replacement conveyors that could increase the rate to handle the rail receiving as opposed to the original truck transfer the mine had depended on.”

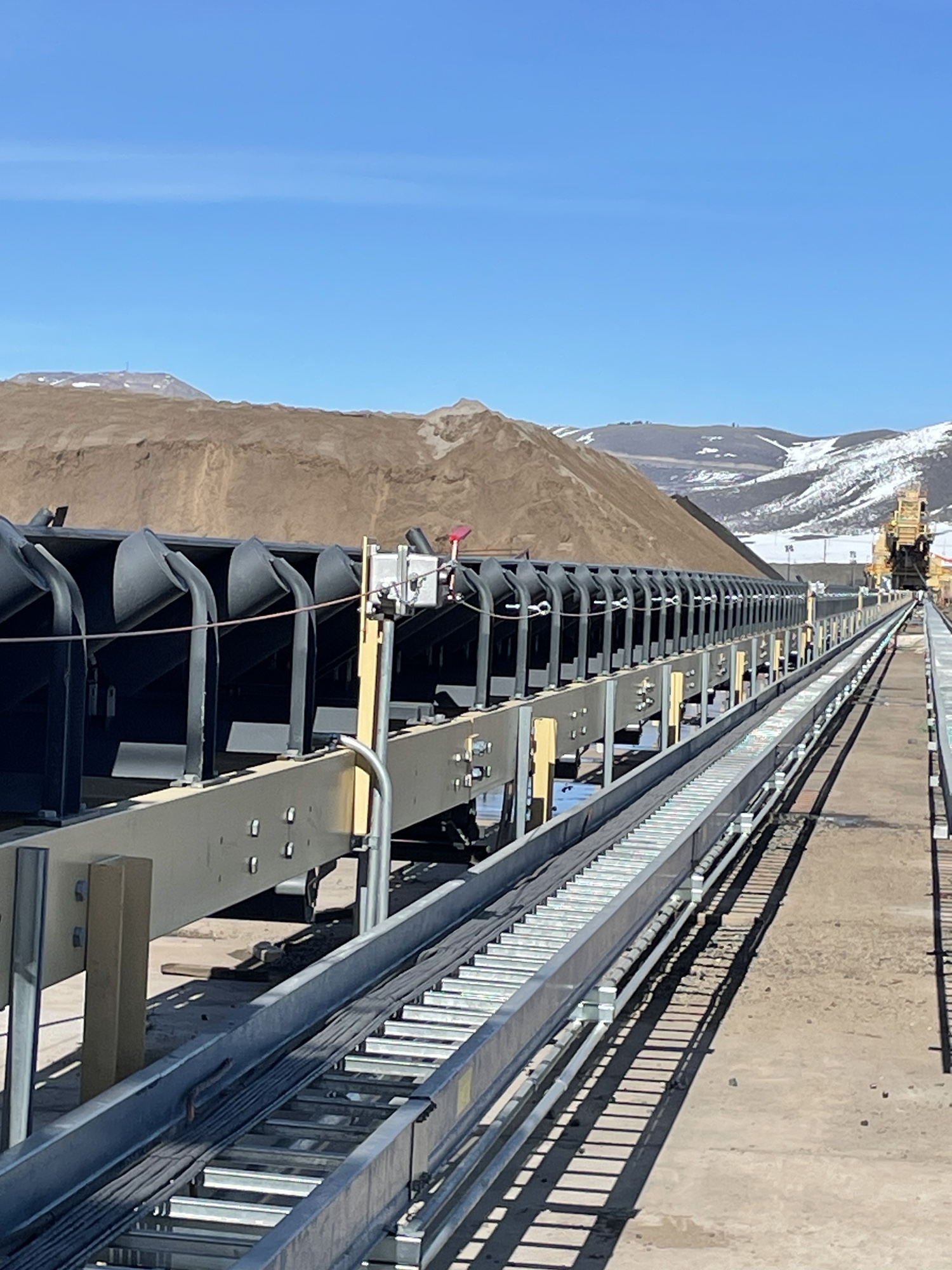

The team’s work began with demolition of the existing conveyor and an existing hopper. Dome Technology then installed a tunnel under the mine-haul road so the new system can convey product from truck receiving to the tripper conveyor and stacker. In total, 3,839 feet of new conveyor was installed.

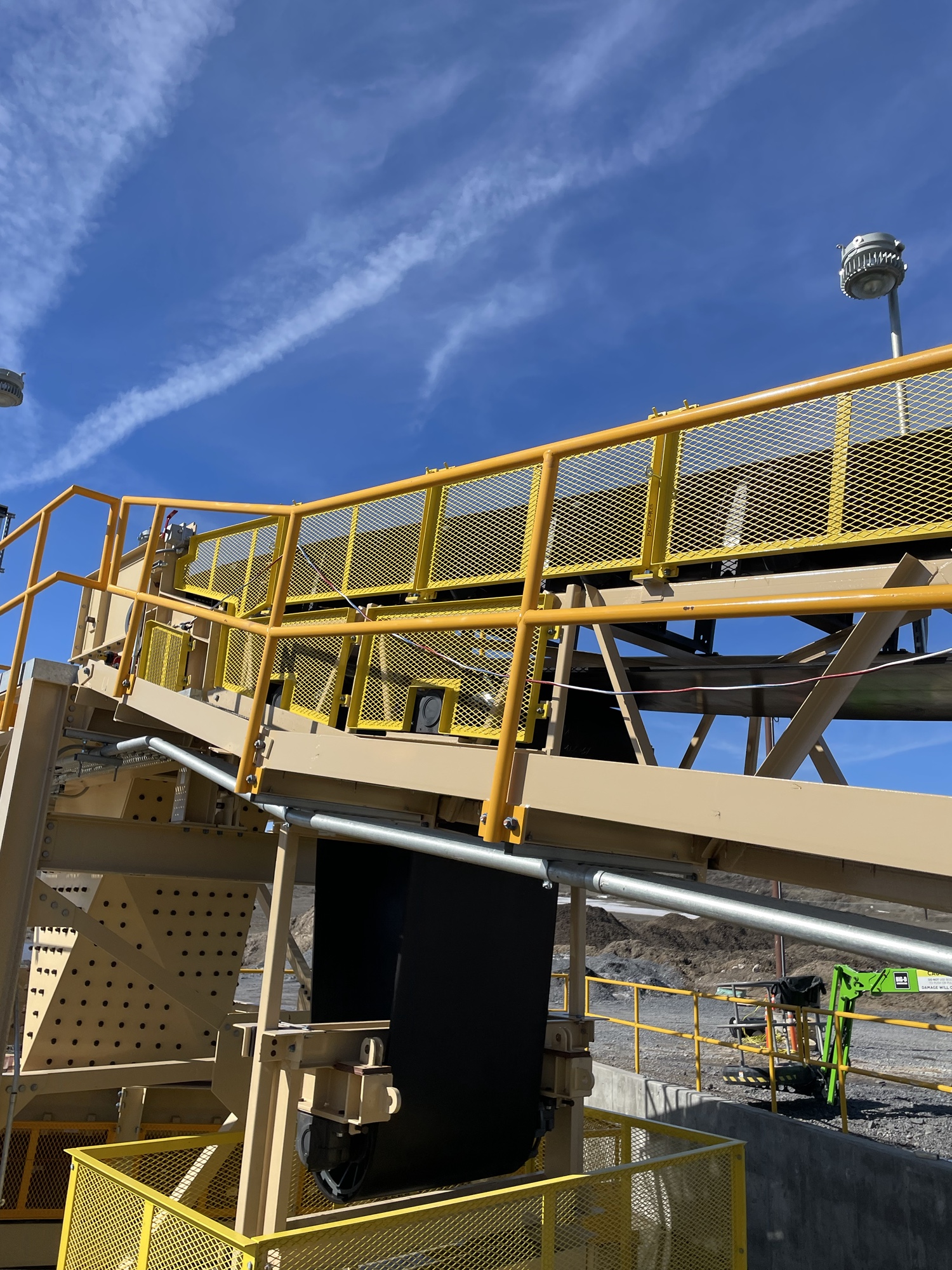

Product stacking in this configuration was also a major consideration. The mining company utilizes an outside pile for stockpiling product when operations pause for winter, but the previous system featured an ageing stacker. Bulk-handling expert Bruks-Siwertell designed the new stacker, then handed over plans to Dome Technology for fabrication and installation.

The new linear stacker system stacks product in piles on either side of the rail, maximizing site space. The company now has a state-of-the-art staging area that complements anticipated business growth and provides a year-round buffer.

In addition, the Dome Technology team designed and installed all concrete, conveyor pits, and footings, as well as assembly and erection of the boom tower and fabricated steel components like ladders, staircases, decking, and handrails.

“We build a lot of DomeSilos for storage, but this is a great example of how we are a turnkey facility provider and can supply storage, conveyance and fabrication,” Harrison said.