Scope of Work

| Domes | Height | Diameter | Capacity |

|---|---|---|---|

| #550 | 117ft | 202ft | 40,000t |

| #550 | 35.7m | 61.6m | 40,000t |

| #551 | 117ft | 202ft | 40,000t |

| #551 | 35.7m | 61.6m | 40,000t |

Two domes a condition-controlled way to store wood pellets in Louisiana

Since its two-dome project wrapped in 2014, Drax’s Port Allen Facility in Baton Rouge, Louisiana, has loaded two ships with wood pellets and will be loading a third ship soon. It’s a process made possible in part by Dome Technology’s design-build approach and material-handling solutions.

“The overall facility has less material handling equipment due to the domes. The domes also require less maintenance and fewer equipment issues, which allow the ships to be loaded on time. All these factors combined reduce the operational costs as well,” said senior project manager Daniel Pittman, who works for Gray Construction, the EPC Drax selected for the facility’s development.

A company committed to reducing its carbon footprint, Drax isn’t motivated by its bottom line alone. Since the source fiber for the wood pellets is renewable, produced from sustainably managed forests, and because pellets stored and shipped from Port Allen will be used as a coal replacement, Drax’s work in Louisiana is good for business and good for the environment too.

But wood pellets can be tricky. Self-heating can be an issue when the product ages in a pile. And moisture of any kind, even from condensation caused by temperature fluctuations in the structure itself, can breakdown the pellets. Therefore, safety systems such as thermal sensors and aeration systems have been installed.

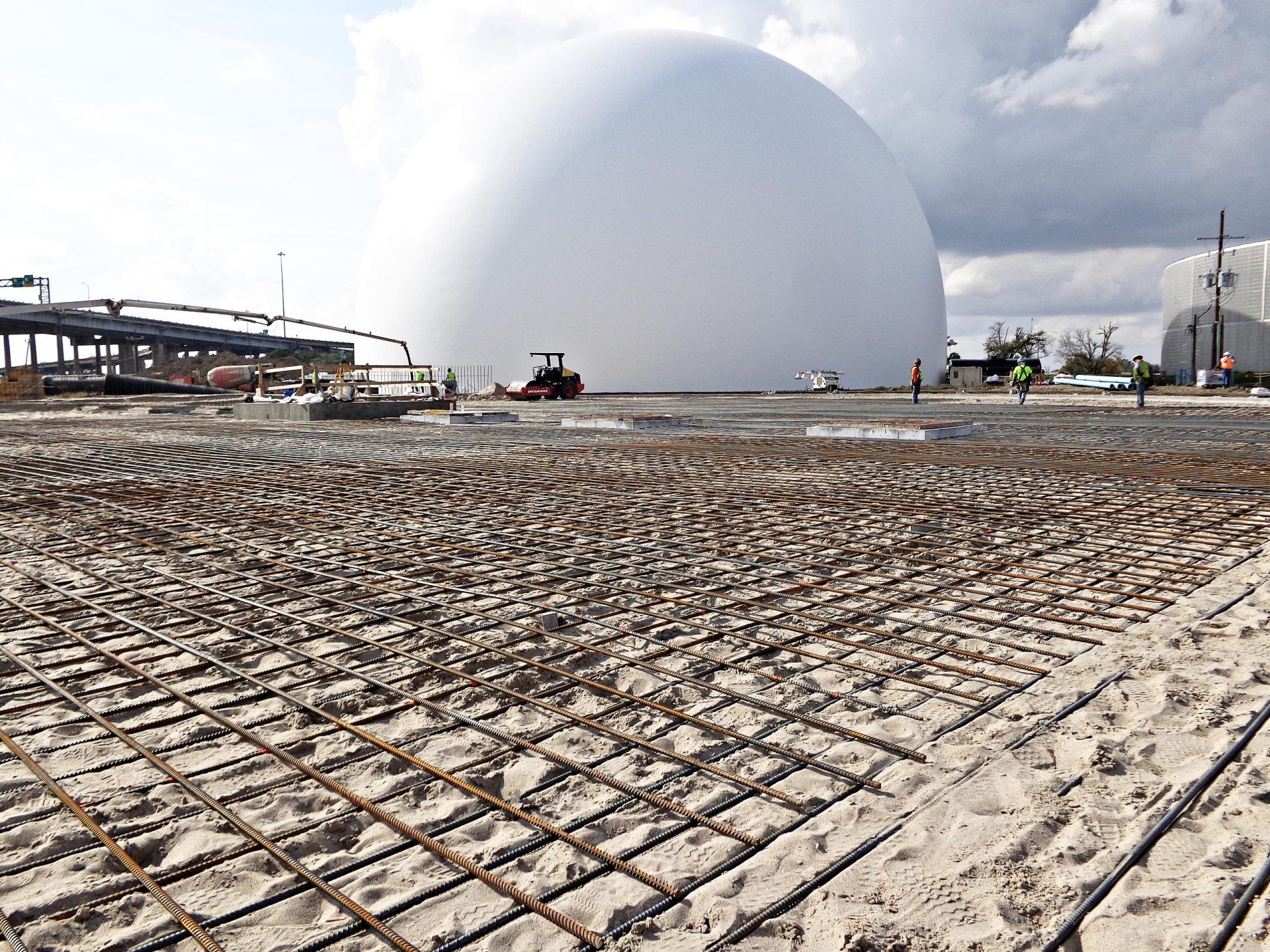

Building a facility near a levee was a challenge too. A location near the Gulf of Mexico means soil is soggy. Traditional foundation methods could be expensive, and then there was the question of whether or not tunnels could be constructed below ground. The design would also need approval from the Army Corps of Engineers due to stipulations necessary for projects built within 1,500 feet of the levee.

With these challenges in mind, Drax and Gray Construction researched bulk-storage options and determined that two 40,000-ton domes would cost less than silos and A-frames for the necessary building size, building cost and equipment cost. Additionally, Dome Technology was willing and able to tackle the project and design a cost-effective foundation system as an alternative to concrete piles.

“Dome Technology was selected due to their innovative engineering design and the project team’s comfort level with their design team,” Pittman said.

Not wanting to use front-end loaders inside the Domes for reclaim as Drax’s main focus was health and safety of staff, they selected a mechanical screw to move pellets from the structures into the tunnels, a system that minimizes the dust produced by moving pellets.

“The customer wanted the facility to have a safe work environment and be as fully automated as possible. Front-end loaders require more employees, higher equipment repair costs, and employees to operate equipment inside the domes in a dusty, hot environment,” Pittman said.

The in-ground tunnels needed waterproofing, and an appropriate foundation was a must. A soil-stabilization ring used to spread the load and prevent soil failure and excessive settlement was embedded 12 feet in the ground, installed in lieu of deep foundations to provide needed stability.

Pittman said Gray Construction management viewed Dome Technology as an important player for getting the project done right. “Dome Technology was not just a subcontractor, but instead played the role of a crucial team member. When issues arrived, they always jumped in to help any way they could,” he said. “Dome Technology provided the design and structure according to the customer’s schedule and budget, which helped make this a very successful project for Gray Construction and Drax. The project was completed in plenty of time to be ready and waiting for enough pellets to be produced to load the first ship.”