Scope of Work

| Domes | Height | Diameter | Capacity |

|---|---|---|---|

| #679 | 135ft | 90ft | 10,000t |

| #679 | 41.1m | 27.4m | 10,000t |

| #680 | 135ft | 90ft | 10,000t |

| #680 | 41.1m | 27.4m | 10,000t |

Renewable-energy giant and repeat customer Drax worked with Dome Technology to complete another wood-pellet facility in the southern United States.

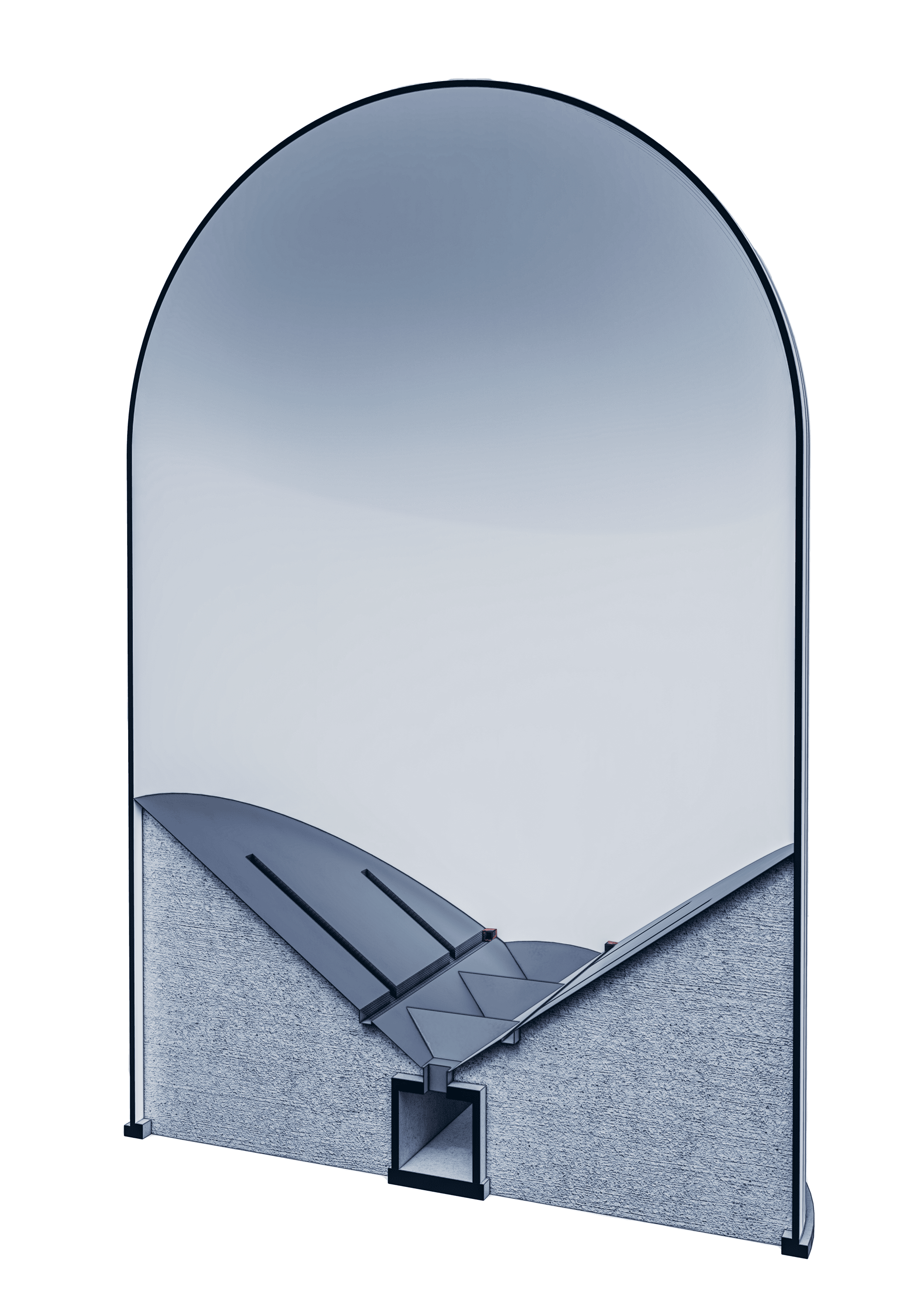

Located in Demopolis, Alabama, this new site features two storage domes 90 feet in diameter and 135 feet tall. Both can store 10,000 metric tons apiece and are designed with a live floor.

Product is reclaimed on a first-in, first-out basis, and the domes are fitted with state-of-the-art safety systems, including aeration, heat sensors, and gas-monitoring sensors.

The site is the epitome of efficiency. Pellets are produced at an on-site plant, then belt-conveyed to a bucket elevator, where they climb the first dome. At the top, the pellets enter a diverter, where they are directed to the desired dome.

Inside both domes, an innovative live-reclaim floor system, dreamt up by Drax and built by Dome Technology, is built around a V-shaped floor so product slides easily across the steel-plated floor. According to Dome Technology sales manager Lane Roberts, the domes’ tall and narrow shape fit the available footprint while still maximizing capacity and live-reclaim capabilities.

“It really does cut down operational costs because you don’t have a lot of equipment to maintain, and you don’t have to have operators in there,” he said.

Pellets leaving the dome are conveyed about 1,000 feet to the river port, where they are loaded onto barges.

The dome also maximizes natural venting. Both domes are fitted with louvered gooseneck vents that control dust naturally; when pressure arises in the dome, it is naturally released through the apex, and dust is captured in the process.