In 2022 the owners of a fertilizer dome in Nebraska were facing a challenge: Their dome roof was sagging and had other structural issues.

Dome Technology was called in to make the structure usable again. The team has repaired multiple domes, built by other companies, that demonstrate structural issues.

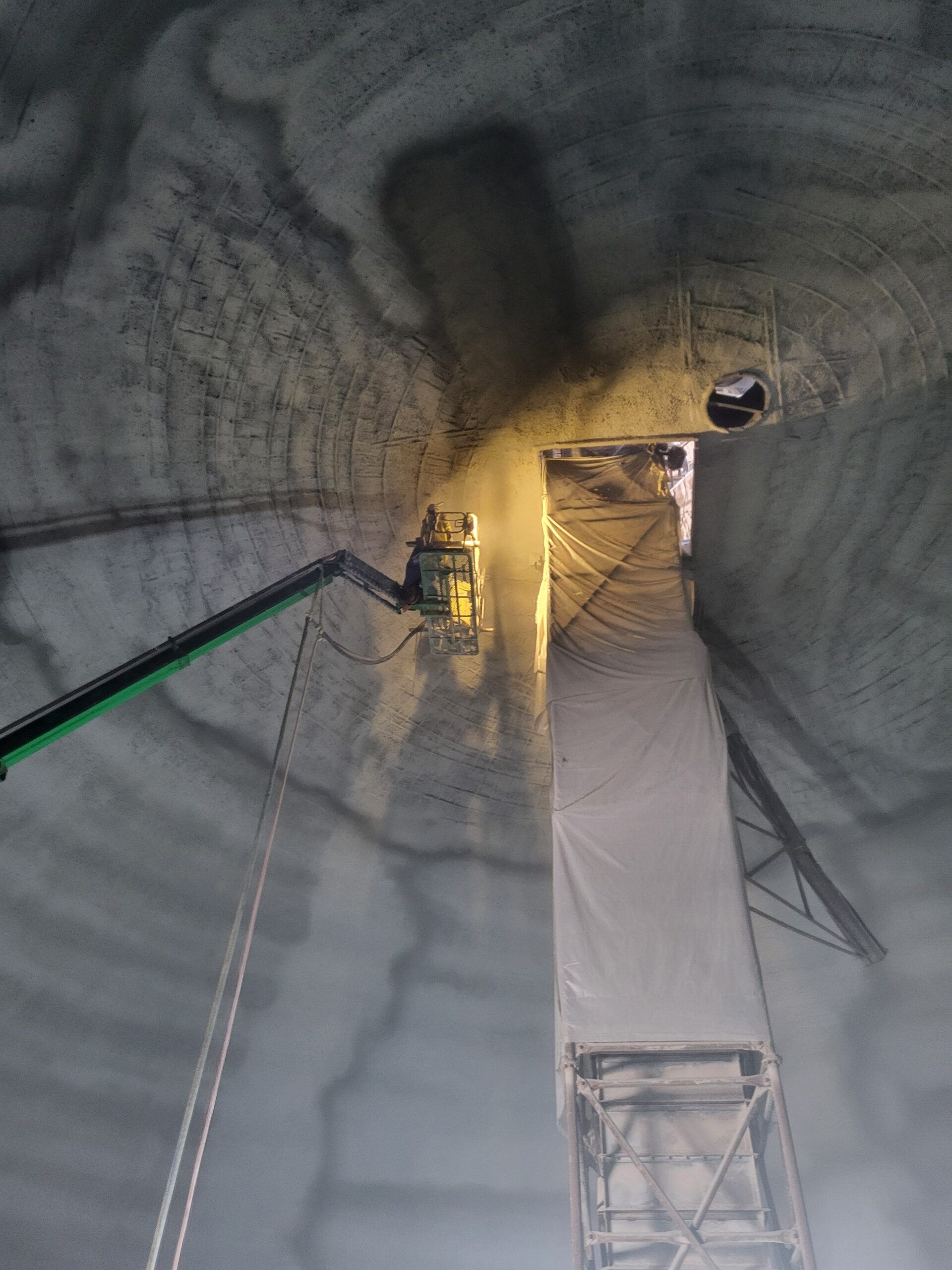

The team started this project with an engineering evaluation, which revealed that the dome-apex sag spanned 40 feet. But the evaluation also confirmed the structure could indeed be salvaged using an innovative approach: Rather than condemn the compromised dome, the team could employ it as the form for a new concrete dome, essentially allowing the team to build a new dome within the old.

Dome Technology typically uses a dome-shaped airform to achieve the shape of the finished structure. High-powered fans inflate the airform, and concrete is applied to the interior surface using the shotcrete method. The finished reinforced-concrete dome is so solid it can withstand hurricane winds and all sorts of product loading and unloading. This time, however, there would be no airform as the team used the existing dome shell as the concrete form.

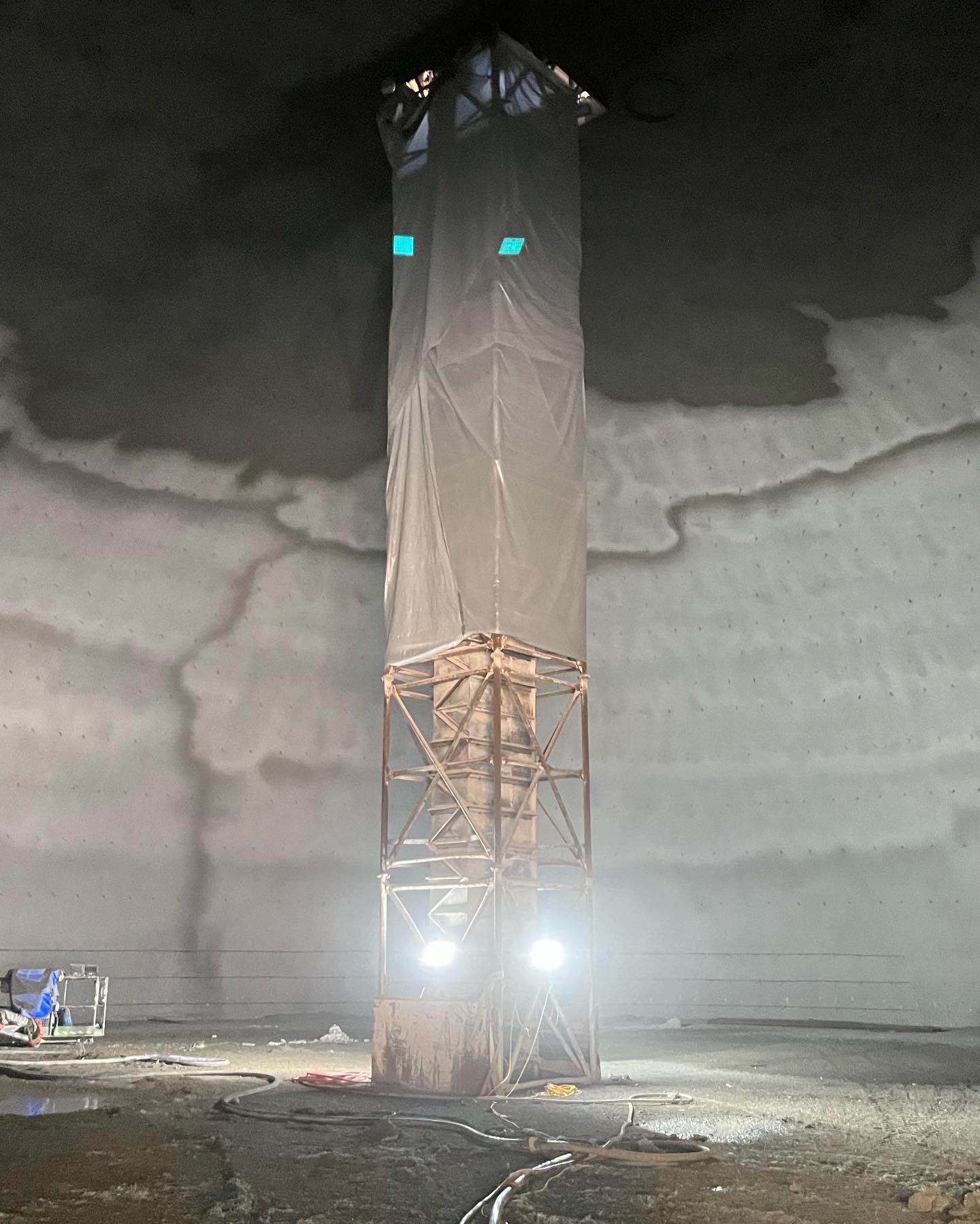

The cost for this repair project would have been much higher if the existing mechanical systems had been removed to accommodate construction. But Dome Technology’s team devised a way to leave the stacker tube intact, saving the customer hundreds of thousands of dollars. “Economically it’s a huge win for the client because it saves them considerable money on demolition costs and the removal and replacement of the material-handling equipment,” Dome Technology sales manager Daren Wheeler said.

Today, current owner Nutrien uses the dome for phosphate storage. They rely on the original reclaim system and benefit from the controlled storage environment, and with rehab finished, they have a storage system with an unlimited lifespan.