In the world of dams and hydro energy, things work well until they don’t.

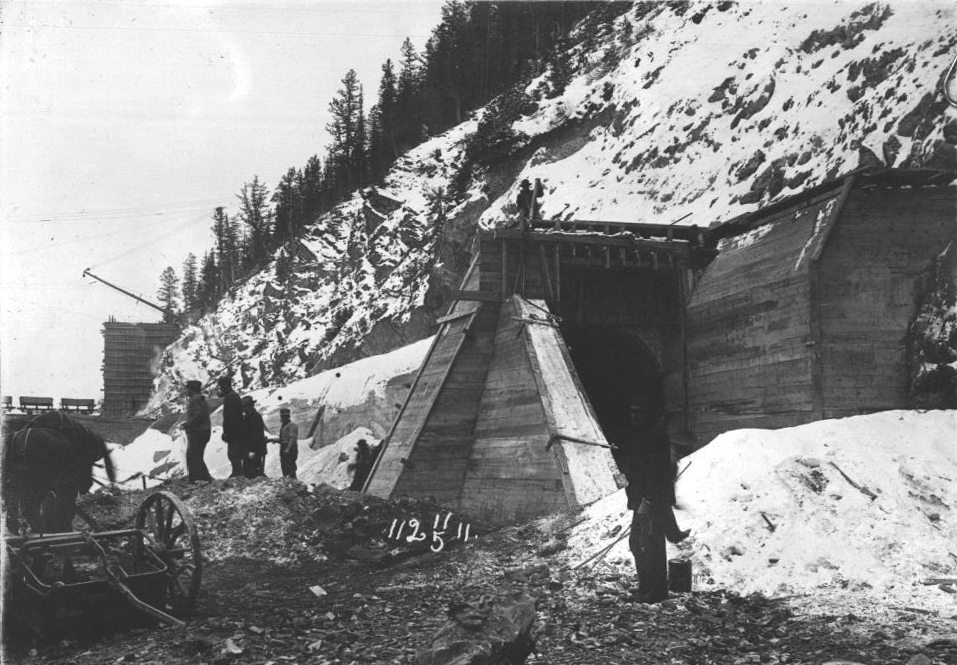

Such was the case with the outlet pipe at Hebgen Dam in Montana. Completed in 1911, the unreinforced concrete pipe lined with 16-foot-long (4.88m) wood-timber staves functioned as the reservoir’s low-level outlet for more than 100 years.

After a 1959 earthquake rocked the region, gates were added to the intake structure at the upstream end of the pipe as an additional control measure; until that point, logs controlling the flow were removed or added as needed to achieve optimal flow, said BJ Cope, senior engineer of hydro engineering at NorthWestern Energy. The dam was operated without issue for many years with many of the original stoplogs in place until four of them broke spontaneously on Labor Day 2008, allowing for unregulated flow. The stoplog failure accelerated the planned and Federal Energy Regulatory Commission-required rehabilitation of the Hebgen Dam intake, spillway, and outlet pipeline.

Dome Technology, in collaboration with Hydro-Arch, was contracted to rehabilitate the 475-foot (145m) tunnel for another century of function by installing a concrete liner inside the pipe. The team started by removing the wood staves, then used chemical grout injections to stop all leaks in the existing concrete. Next, the team lined the bottom of the tunnel with prebuilt rebar cages. Concrete was then placed and finished on the lower portion of the tunnel. Once set and finished, crews did the same for the top portion of the tunnel, applying concrete to the upper curve using the shotcrete method. In fact, “it was our ability to be able to spray the shotcrete that made us valuable on this project,” said Dome Technology project manager Jason Craig.

The result is a one-foot-thick (0.3m) layer of steel-reinforced concrete lining the entire outlet pipe, which is now 10 feet, 8 (3.3m) inches in diameter. The project was completed in less than four months, and the tunnel rehab is “essentially an incremental reduction of risk to this structure and the facility as a whole,” Cope said.

The outlet-pipe rehabilitation was the third and final phase of the rehab project, and NorthWestern Energy can now be more confident in the efficiency and robustness of the dam and its systems.

“This extensive project provides strong assurance that the dam operation is safe, which is important to the company and to the many stakeholders and recreationists who use Hebgen reservoir and the Madison River below the dam,” said Butch Larcombe, NorthWestern Energy manager of external communication.