Scope of Work

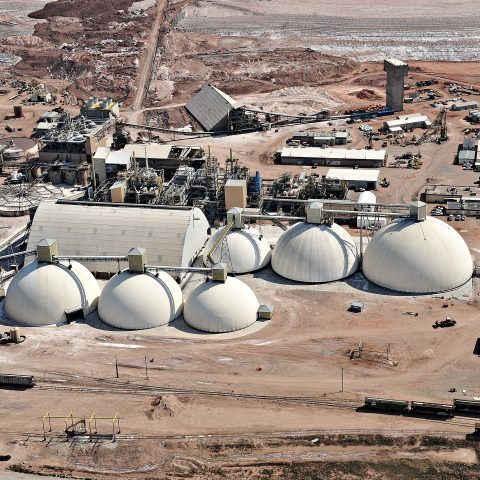

| Domes | Height | Diameter |

|---|---|---|

| #463 | 90ft | 180ft |

| #463 | 27.4m | 54.9m |

| #473 | 57ft | 120ft |

| #473 | 17.4m | 36.6m |

| #474 | 65ft | 130ft |

| #474 | 19.8m | 39.6m |

| #475 | 76ft | 152ft |

| #475 | 23.2m | 46.3m |

| #476 | 60ft | 120ft |

| #476 | 18.3m | 36.6m |

| #477 | 96ft | 152ft |

| #477 | 29.3m | 46.3m |

| #517 | 76ft | 152ft |

| #517 | 23.2m | 46.3m |

| #518 | 60ft | 120ft |

| #518 | 18.3m | 36.6m |

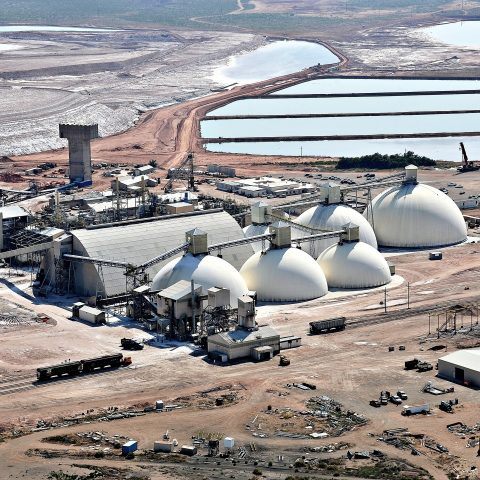

Series of domes makes it easier for Intrepid Potash to separate product

After a microburst damaged Intrepid Potash’s facility in Carlsbad, New Mexico, company executives needed a storage solution that could sustain weather-related events and other accidents. Their research led them to choose not one dome but a series of domes for Carlsbad, domes that are still going strong after nearly a decade of operation.

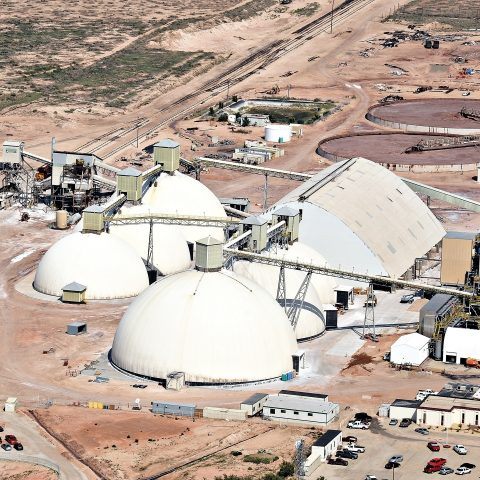

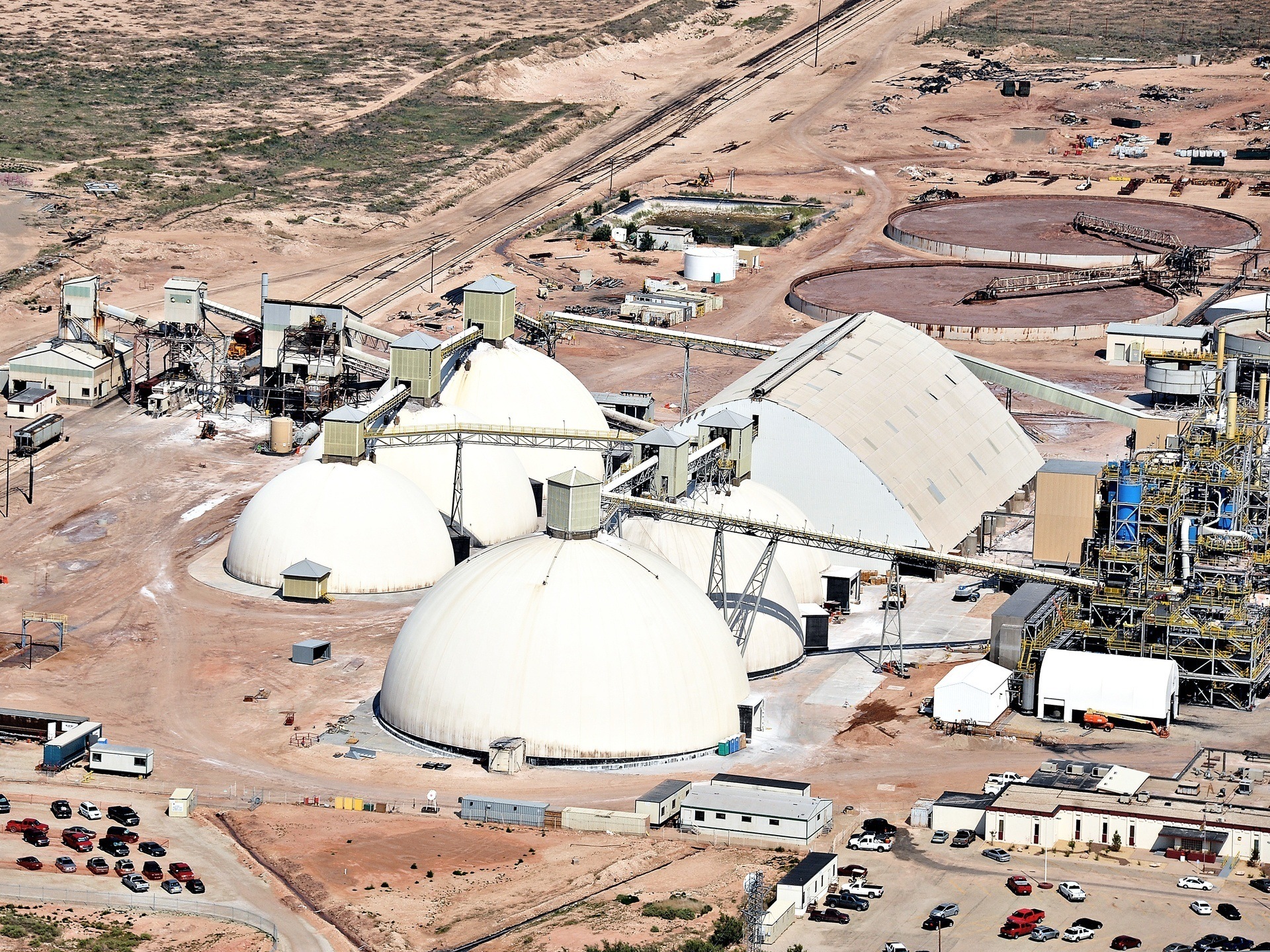

Intrepid Potash stores two different product lines—sylvite/potash and langbeinite—in three different associated sizes each, so keeping product separate was key. While making the change in storage facility, the company opted not for one dome but for six, an improvement over the previous model where one very large warehouse had divisions inside. By building multiple domes, product could be kept separate and distinct.

To make the project work, dome placement was key, and “the big thing was to fit the current application. The domes had to overlay in one set of previous tunnel networks—that was a key requirement,” said Robert Baldridge, Intrepid Potash general manager for New Mexico operations. Careful design made that request possible and productive.

Quality control was a major consideration and one that stood out to Baldridge. For instance, rather than bringing in concrete material by truck, Dome Technology set up a batch plant onsite, saving the customer money from ordering from the only batch plant within driving distance. Opting to make its own concrete was better “from a convenience standpoint and a cost standpoint,” said Dome Technology vice president of construction Bryan Butikofer. “When you batch your own concrete, you’re guaranteed to get fresh concrete at any time you need it.”

In Carlsbad today, the raw product is mined, then refined in a processing facility to remove waste material before being moved to the appropriate dome for storage before sale. From the domes, screw conveyors and underground conveyors transport the potash to a rescreening facility that ensures product size and quality before being loaded onto rail cars or trucks.