While Dome Technology worked on a McInnis Cement project in Rhode Island, the company called Dome Technology with an unrelated question: Could the team also install an additional truck loadout lane at an existing terminal in The Bronx, New York?

The Bronx terminal was already a unique facility in a unique position, situated “in deep enough water to enable berthing of large vessels, which is not the case for our major competitors,” Forlini said. Expansion would bolster its potential even more.

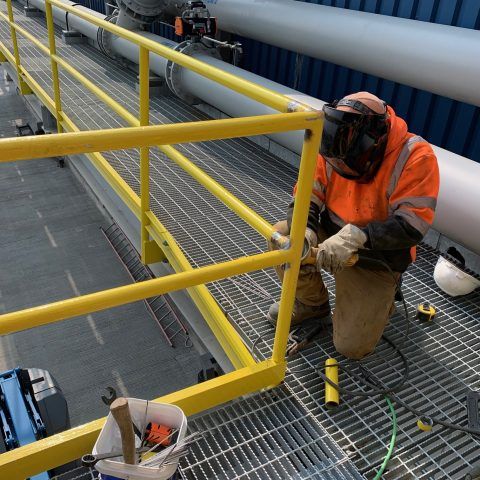

Within 130 days of construction starting, Dome Technology completed an additional truck bay for the Bronx facility, including concrete ramps and footing for the structural steel, mechanical equipment, piping and structural-steel installation. The team executed all structural and millwright work, and operations at the facility were not interrupted during construction.

This project highlights Dome Technology’s expertise outside its most obvious skill set: building bulk storage. “Our name is Dome Technology, and there isn’t a dome on the site. It was all about mechanical structural installation for material handling,” said Dome Technology vice president of operations Dan South.

With a fabrication shop on the same campus as corporate headquarters, Dome Technology engineers and construction managers work closely with team members who build features like structural-steel structures, walkways, bridges, stair towers, mechanical equipment, and more. This means customers are more likely to end up with an entire project that operates seamlessly.

“We’re tied closely to the dome, so we know what (customers) want, and we know how everything interfaces,” said Dome Technology shop operations manager Kirby Sheldon. “We’ll see problems other fabricators won’t see.”

The second Bronx truck bay is in use now, and operations are running more smoothly and more efficiently. “We are doing between 60 and 70 trucks a day with no lines building up. It’s helped tremendously,” said terminal manager Stanley Sisson.