Scope of Work

| Domes | Height | Diameter | Capacity |

|---|---|---|---|

| #1320 | 137ft | 157.5ft | 75,000t |

| #1320 | 41.8m | 48.0m | 75,000t |

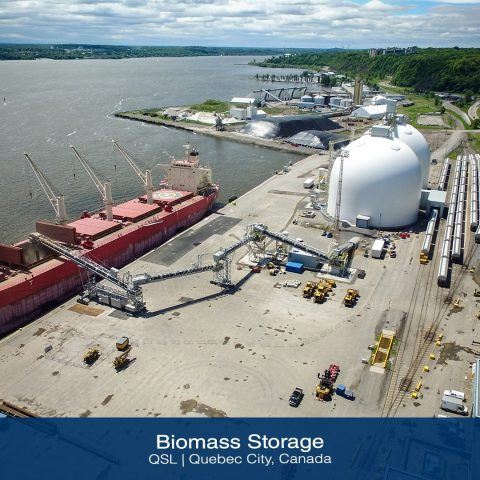

From the beginning of its portside project in Quebec City, the challenge for maritime terminal operator and stevedore QSL was selecting a wood-pellet storage solution that checked all the boxes as both a smart financial investment and a good steward of the community.

First, the company required 75,000 metric tons of storage. Steel silos were an option, but a pack of six to eight would be needed to store that tonnage. Since the site is located near a historic district with a park and residential area, something more aesthetically pleasing was in order, and a DomeSilo™ fit the bill.

“We needed something nicer than a series of silos, so that was the main concern. Then also because of the size of storage, we needed something solid that would last a long, long time,” QSL director of engineering Eric Lapointe said.

Second, QSL was concerned about product integrity and wanted “something that wouldn’t attract too much heat from the sun. A concrete system like the dome was ideal to store the pellets. Because we can have no water infiltration whatsoever, domes are ideal for that as well,” Lapointe said.

Controlling dust was front of mind because of the nearby neighborhood. QSL liked the seamless nature of the dome, but the tightness presented its own challenge in managing off-gases and dust inside the domes. After a United Kingdom firm concluded the amount of fuel in a worst-case scenario would require vents 1/3 the surface of the dome, QSL sought an innovative approach. “We said, ‘Let’s try to minimize the amount of fuel so that if there is an explosion, we will need much smaller vents,’” Lapointe said.

That’s when Dome Technology presented the idea of the filling tube. A belt conveyor moves pellets into the top of the domes, where they enter a 10-foot-diameter tube running down the center of each dome. Product rolls through openings incrementally located on the tube and into the pile, resulting in smoother, more even pile and less dust production. When reclaiming the pellets, they are first drawn down from the stacking tube, then from each opening on both sides of the tube. This causes less shear friction of the pellets, minimizing further degradation.

For additional dust management, “we installed a dust-collection manifold inside that tube so that (with) any pellets that come out of the tube, there’s much less dust,” Lapointe said. “There could still be an explosion, but the dust cloud would just be what’s inside that filling tube, so the volume of the cloud would be much, much smaller.” With the filling tube installed, the vent sizes dropped down and so did the venting cost.

Testing for dust concentration at four levels inside the dome all came back well below the minimum explosion fine concentration inside the dome. “We kind of got rid of the risk at the base. Instead of trying to mitigate if there is an explosion, we tried to prevent it from happening,” Lapointe said.

Choosing a dome meant better dust control, better product protection, and lower construction costs. Dome Technology engineers were able to design domes that didn’t require foundation systems—a cost that would have been a given with silos. The result has been better than QSL expected. “Because there are no piles, we anticipated some settling of the soil, and based on calculations, we thought it would be about a foot. We got about four inches,” Lapointe said, adding that continual surveying produces the same result.

Providing advanced features and customized storage is part of Dome Technology’s mission with every project. “For nearly four decades we’ve relied on a collaborative approach with companies—they’re in the driver seat, and we help navigate. In every project Dome Technology incorporates innovative technology to maximize storage capacity and system performance with an economical solution,” said Dome Technology CEO Bradley Bateman.