One of the hallmarks of quality workmanship is the number of repeat customers it generates, and Dome Technology has worked with some of the biggest industry leaders on multiple projects. This is the fifth part in a five-week series highlighting a lineup of Dome Technology customers who’ve come back for more.

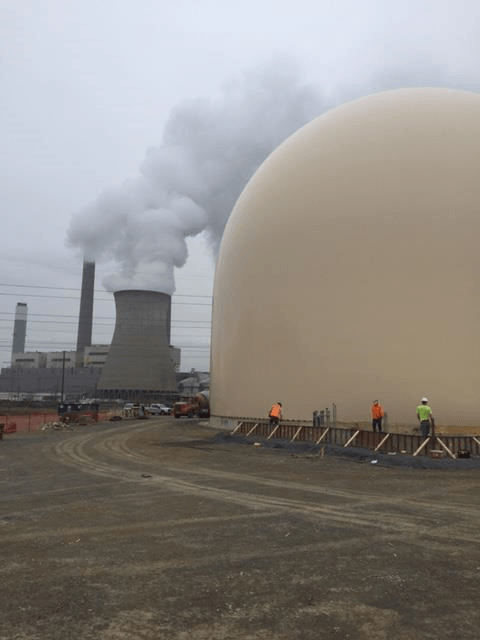

Boral Material Technologies has contracted with Dome Technology three different times to build fly-ash storage. The most recent project required a dome near Cartersville, Georgia, standing 120 feet in diameter and 100 feet tall with a storage capacity of 30,000 English tons.

According to Dome Technology sales manager Lane Roberts, Boral was looking for an economical storage solution. Boral’s director of engineering services Gary Gentry agrees. A dome would provide the amount of storage needed to meet operational needs, allowing Boral to “maximize storage for the footprint at a cost that’s susceptible to return on capital investment,” he said.

Based on front-end engineering, Dome Technology’s team was able to identify the ideal foundation type for the Georgia dome. The site is comprised of karst, where water has dissolved portions of the limestone and left voids in the rock; this can result in sinkholes and unsure foundations. “We looked at different kinds of deep foundations, and (Boral) agreed that only one kind would work: micropiles,” Roberts said.

In 1997 Dome Technology built a fly-ash dome for the company in Walnut Cove, North Carolina, measuring 165 feet in diameter and 82.5 feet tall. In 1998 Dome Technology a dome was built in Fontana, California, measuring 94 feet in diameter and 53 feet tall.

According to Gentry, Boral is a repeat customer based on the experience working with Dome Technology in the past and “because of the professionalism and success of the previous two projects.”

For more information on fly-ash and cement storage, visit our Stored Products page. To see more projects for Dome Technology customers, visit our Projects page.