Construction always impacts the environment, but a dome from Dome Technology is more environmentally responsible than conventional structures and building methods in these ways:

1. Use of less material during construction.

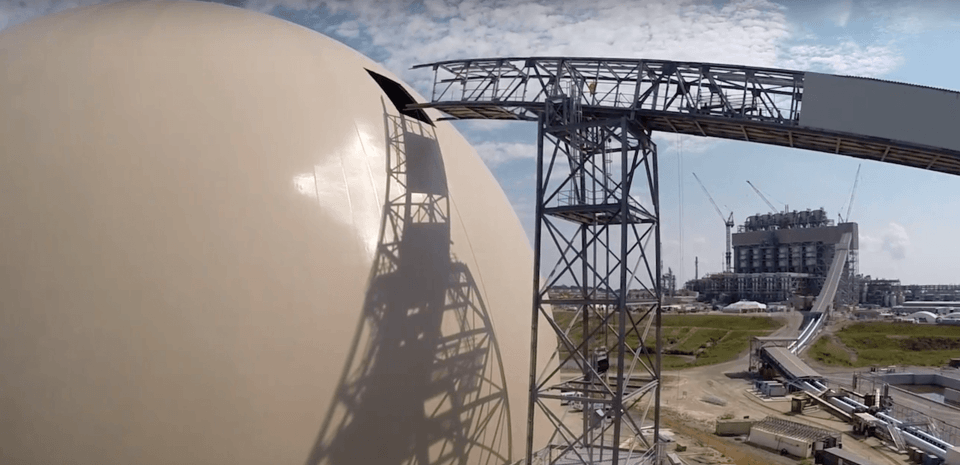

The dome’s efficient double-curvature structure conserves construction materials by using less material to enclose more storage volume than any other comparative structure.

2. Less construction material waste.

As shotcrete and rebar are installed on the inside of the dome’s airform, significantly less waste is generated than compared with conventional construction. This not only saves the customer in overall project costs but also provides less waste in local landfills.

3. Containment of potentially harmful environmental contaminants.

The continuous single-ply PVC waterproofing membrane of the dome ensures complete waterproof protection for the reinforced concrete shell and consequently the material stored within. Combine this with the catch basins and drains, which are to be installed at each entryway, and the dome provides for excellent containment and protection of potentially harmful environmental contaminants.

4. Low maintenance.

A mold-resistant UV-protective resin coats both sides of the membrane, providing long-term protection from the outside environment as well as securing whatever material is stored inside. This membrane and the shell itself require a fraction of the maintenance when compared with traditional construction.

5. More storage with a smaller footprint.

Product can be stored against the vertical wall and into the dome roof as well, which provides for efficiently storing more product using a significantly smaller footprint. Valuable property and resources are preserved because of the dome’s strength to withstand the pressures of product being stored inside the entire dome structure.

6. Heat, fire, and explosion protection.

The reinforced concrete shell uniquely maintains structural integrity in extreme heat and fire conditions. Its designed strength provides superior structural integrity in the event of a fire, often eliminating the need for complete reconstruction in the event of a fire.

7. All-weather construction method.

Once the airform has been inflated, all construction work is completed from the inside in a controlled environment. This encourages and facilitates efficient construction sequencing, improved quality control, and a safer work environment; it also virtually eliminates construction delays caused by weather, which reduces the amount of time machinery, generators, and the like are running at the site.

For more information about our environmentally responsible bulk-storage domes, visit our Key Benefits page.