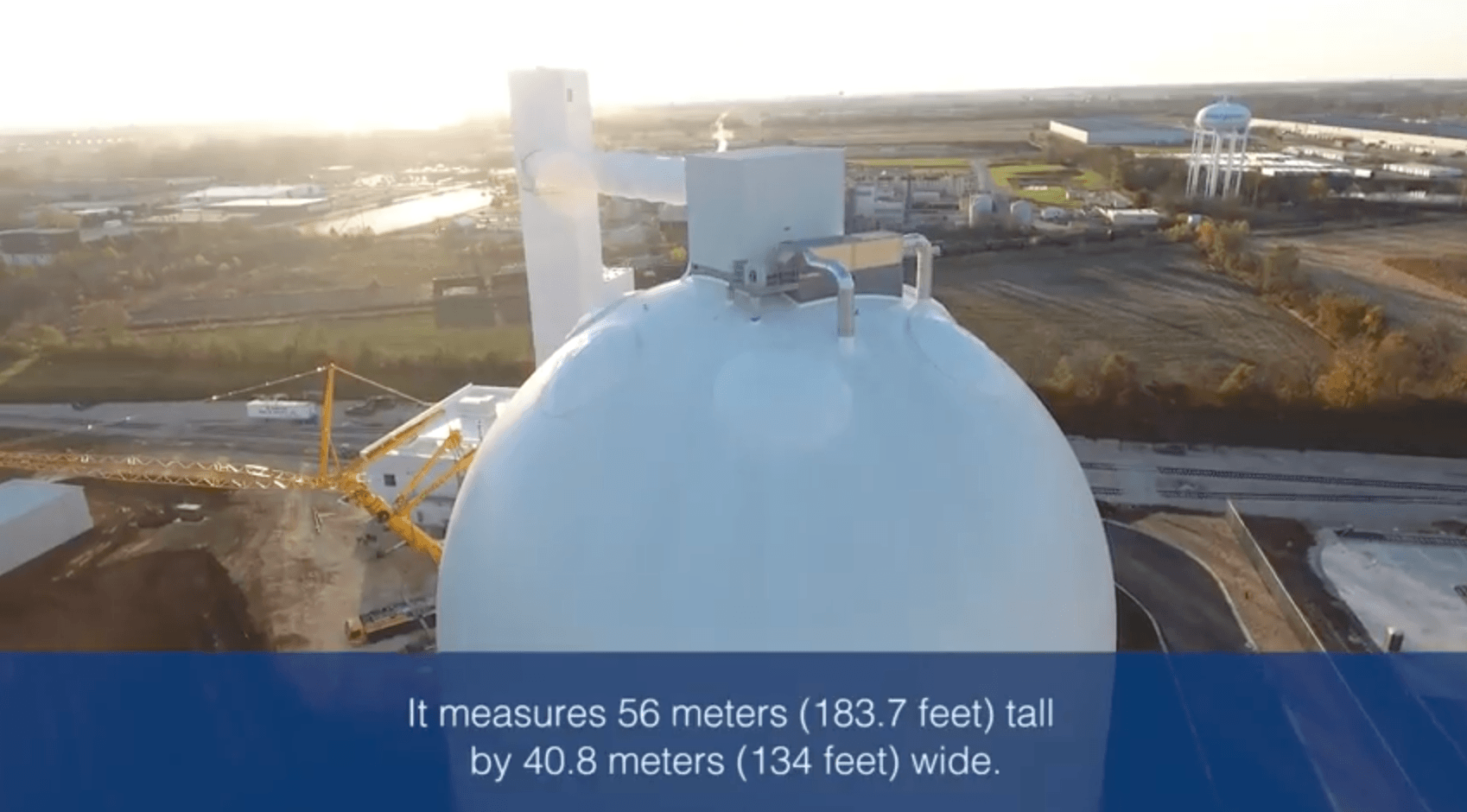

Dome Technology has finished constructing a dome standing 134 feet tall and 183.7 feet in diameter for American Crystal Sugar Company. The dome can store 60,000 metric tons of sugar, and although ACSC owns the facility, United Sugars Corporation oversees operations. Click here for a video about the dome and its systems.

The dome is equipped with mechanical systems providing a fill rate of 200 metric tons per hour and a reclaim rate of 150 metric tons per hour.

Client requests + customization

The dome is a first for American Crystal Sugar Company, which previously relied upon concrete silos and steel Weibull bins. According to Aaron Bjerke, who oversees business development for ACSC, the cost of constructing a dome versus concrete silos was equivalent per unit stored, but savings could be found in the material-handling systems. Because the company will be able to achieve its storage needs with one dome, just one handling system will be installed, as opposed to a redundant cost of one material-handling system per silo.

Meeting customer expectations

In addition to building the dome, Dome Technology installed the reclaim screw, a clean-sweep model made of stainless steel to complement food-safe requirements. A food grade-quality coating was sprayed on the entire inner dome shell, and the applied VersaFlex product ensures cleanliness in storage. The dome also features temperature and humidity control, a dust-collection system, and explosion panels.

According to an ACSC press release, the dome will not be attached to a producing sugar factory, making it the United States’ largest freestanding sugar-storage facility.