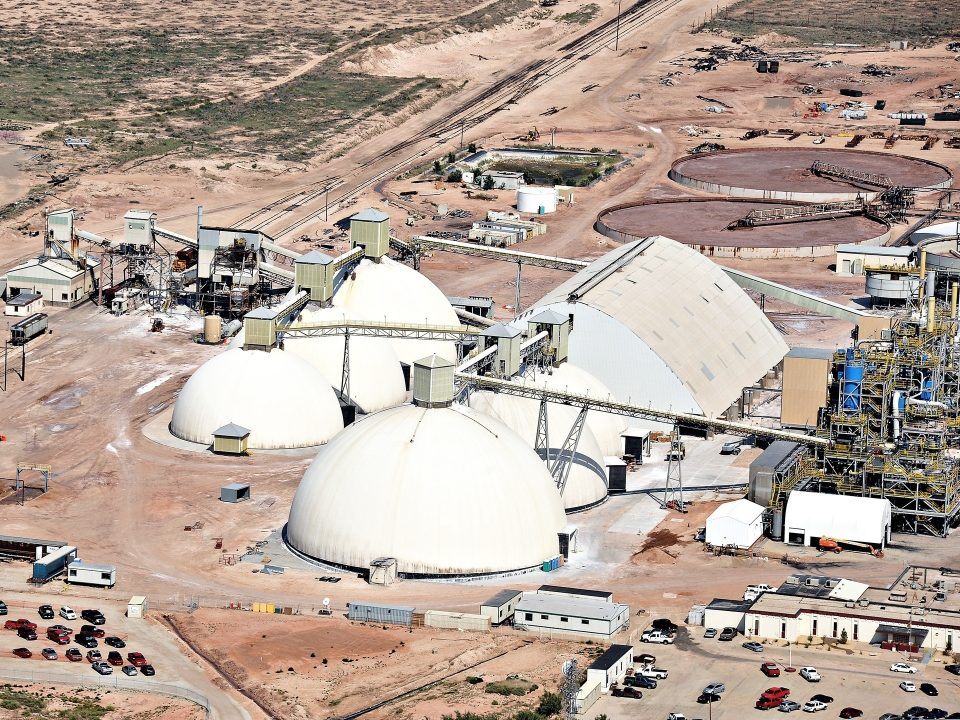

Shaping up nicely: Two domes provide ample fertilizer storage, product separation for one company in the U.S.

By Rebecca Long Pyper for Dome Technology

For one major chemical company in the United States, crystal bridging was really becoming a problem.

The company was shipping low-density ammonium nitrate via train, but because they did not have adequate means for curing, the product clumped together via transit, making it difficult to remove upon arrival to the customer.

In an effort to solve that problem in a big way, Dome Technology was contracted to build one dome, and eventually a second one, that would provide ample storage and the ability to keep different types of ammonium nitrate separate.

Initially the plan was simple: To construct a single dome designed to hold low-density ammonium nitrate. Dome Technology built the dome, which stands 99 feet tall and 198 feet in diameter and has a maximum storage of 16,000 tons. The dome is fed at the apex, where product is stacked in a kidney-shaped pile. A chute rotates to lay the pile in a thin layer that allows for better cooling, thus avoiding a deep pile where the center would never adequately cool. Maximum convey rate to the dome is 450 tons per day, and the reclaim rate is 800 tons per day.

The dome is temperature and humidity controlled, and a smoke-detection system ties in with louvers so that should fire be present, a fan will kick on to blow out fumes that could explode. The pile depth is capped at 45 feet to prevent degradation.

The low-density product cures in 10 to 20 days, then is ready for shipping via truck or rail to be used in explosive applications. By allowing it to adequately cure, crystal bridging is far less likely, resulting in better flow and a better product for customers.

As construction for Dome 1 was underway, the customer decided a second dome would be a good idea, this one to store high-density ammonium nitrate, particularly to keep up with spring-season demand.

Product in the second dome can be stacked deeper and is center filled because it doesn’t have the curing issues that low-density ammonium nitrate does. The customer fills the second dome completely to fully utilize the storage volume, Aagard said.

Both domes feature a ring-beam foundation, standard in dome construction, and soil improvement was completed prior to construction to set the stage for solid foundations. For both domes, a front-end loader reclaims product, dumps it into a hopper, and the hopper feeds to conveyors. But having two separate domes with distinct reclaim systems ensures that product types are never mixed.

In 10 months both domes and their conveyor systems were complete, customized specifically to the customer’s requests and providing the protection both types of ammonium nitrate demand.

“As we have seen over the course of several years, Dome Technology can offer solutions for material storage and handling for a wide range of storage needs. I am happy that Dome Technology was able to offer and provide solutions for this facility in storing their product,” Dome Technology project manager Jason Craig said.

Fertilizer storage + domes

Ammonium nitrate in general shows two faces, one that helps things grow and one that can make things explode. Whether destined to become an ingredient in fertilizer or a component for explosives, ammonium nitrate’s hygroscopic nature requires a controlled, secure environment.

More companies are seeking the benefits of steel-reinforced concrete domes that exceed those found in flat storage or steel bins. Unique and proven construction methods and materials contribute to a dome’s strength and flexibility of use. Here are a few key benefits of a dome for fertilizer storage:

Space requirements and storage ability

Domes store a large volume in a smaller footprint, stacking product deeper and taking up less property at the site. While some customers require three to five warehouses to store product, one dome will likely accommodate the same amount of material. Dome engineers are experts on stored products and will help customers determine how much product can be safely stored within a structure.

Domes can also be engineered with innovative load-in systems that ensure pile depths are within the appropriate parameters for product integrity. This is especially important for more volatile forms of ammonium nitrate.

The double curvature of a dome lends itself to the ability to build up, rather than out, and that curve provides strength at all points of the structure. The entire interior of a dome, then, can be used to contain product, so a dome will hold store more than a silo of similar diameter and height. In essence, the more fertilizer storage the customer wants, the more competitively priced a dome will be.

The preceding is an excerpt from a feature published in the July/August issue of World Fertilizer. For the full text, click here. For information on additional benefits, like strength, foundation options, moisture protection, fire prevention, material-handling solutions, and cost savings, click here to download the full article.